From June 17th to 21st, I had the opportunity to explore Portugal in a truly special way. Starting in Lisbon and continuing to Porto, I visited the world’s largest cork producer, Amorim. This journey took me through 9 cork factories, a cork oak forest, and two renowned wineries, giving me the chance to meet extraordinary people, including the company’s president, Antonio Amorim, who represents the fourth generation of his family.

First and foremost, I would like to thank Antonio and Ricardo Valente, who are responsible for Amorim Romania (as well as Bulgaria, Moldova, and Turkey), for this extraordinary experience. At their invitation, I had the honor of visiting and discovering Amorim. I also thank everyone involved in organizing this incredible experience.

A Factory for Every Cork

I began my adventure in Lisbon, the vibrant capital of Portugal, from where we headed to our first destination – one of the cork stopper factories. The first impression was one of complexity and refinement, with enormous attention to detail, but I was to learn that things were, in fact, much, much more complex. After visiting eight more cork stopper factories – each dedicated to a certain quality standard or destination, from spirit bottle stoppers to insulating – I began to understand just how complex the Amorim ecosystem truly is.

We are talking about a company that sells 6.1 billion cork stoppers annually, and cork stoppers are not the only Amorim product. The company has about 5,000 employees, 72% of whom have ISO 45001 or SA 8000 certifications, functioning as a family and sharing the same values in unison. Amorim manages over 8,000 hectares of cork oak forests, ten cork preparation (stabilization) points, 20 factories, and 63 distribution companies covering 30,000 clients in 100 countries. Undoubtedly a giant, but one that seems more interested in sustainability than in its own brand. The name Amorim is mentioned less frequently in discussions than investments in forest development, irrigation, recycling, renewable energy, and a safer, cleaner eco-future.

The Life of Cork

After the visit to Lisbon, we traveled to Porto, where we visited more factories and a cork oak forest, learning about the life cycle of cork and how it is sustainably harvested. The life of cork as a raw material begins when the tree is first stripped, traditionally at the age of 25 – when the trunk’s circumference, 1.3 meters above the ground, is at least 70 cm.

Subsequent strippings occur at intervals of at least nine years, between May and August. The stripping process is manual, ancient, and requires experienced hands to avoid damaging the bark or the tree.

The cork harvesting process has several stages:

- Opening: The cork is cut vertically along the deepest groove, separating the cork plank from the bark.

- Separation: The plank is separated by inserting the edge of the axe between the plank and the bark with a twisting motion.

- Sizing: The size of the cork plank is defined by a horizontal cut.

- Stripping: The plank is carefully harvested to avoid breaking it. (The larger the plank, the higher its commercial value.)

- Waste Removal: Cork fragments at the base of the trunk are struck several times to remove any potential parasites.

- After stripping, each cork oak is marked with the last digit of the year the cork was harvested.

A Harvest Per (Almost a) Decade

The cork oak tree can be stripped 15-18 times throughout its life, at nine-year intervals. At the age of 25, the cork is harvested for the first time, yielding virgin cork. This is primarily used for flooring, insulation, or other industrial applications due to its irregular structure and extreme hardness. At 34 years old, the second stripping yields secondary cork, which is used for composite materials in construction and other uses (cork is an important architectural element in the new cruise ship terminal in Lisbon, designed by top architect Carrilho da Graça). At 43 years old, the third stripping produces "amadia" or reproducing cork, ideal for producing quality stoppers.

Sustainability and Research at Amorim

An essential aspect of the visit was understanding the importance of sustainability in the cork industry. Amorim is committed to protecting cork forests and promoting responsible harvesting practices. Cork is a natural and renewable material, and the production processes are designed to minimize environmental impact. The company continually plants new trees, contributing to pollution control and maintaining a healthy ecosystem. Amorim has already planted an additional over 400,0000 cork oaks, and the approved and ongoing Forestry Intervention project plans to plant 1,000,000 cork oaks by 2030. In the same program, Amorim has intervened in various ways onto over 1,400 hectare, and the program is scheduled to continue in the following years.

Amorim is renowned for its intense research, development, and innovation (R&D) activities. The company’s latest studies have brought surprising information to wine lovers, such as the fact that it doesn’t matter if a bottle is aged vertically or horizontally. This is evidently a side effect of the improved quality of cork stoppers over the last 30 years and the complete elimination of TCA (the compound that causes the famous "cork taint").

With TCA issues resolved, the priority has become understanding how cork positively affects various beverages, as explained by two of my guides on this journey, Miguel Cabral and Ernesto Pereira.

Cork Stoppers for Sparkling Wines

Amorim produces cork stoppers specially designed for sparkling wines, capable of withstanding 6 bars of pressures. These stoppers are made from an agglomerated cork body with natural cork discs on the side in contact with the wine. The production process is meticulous and includes rigorous quality controls to ensure optimal chemical and physical performance.

Amorim’s sparkling wine corks combine cutting-edge technology with the intrinsic quality of cork, ensuring a more natural and environmentally friendly product. Additionally, the stoppers undergo advanced cleaning processes and exclusive technologies such as CORKNOVA®, ROSA+FBT, and NDtech® to eliminate volatile compounds responsible for cork sensory anomalies.

More Than Just Stoppers

The Amorim Group is the undisputed leader in the global cork industry, significantly contributing to sustainability and innovation in this sector. Founded in 1870, the company has grown steadily, investing in research, innovation, and design. Amorim produces stoppers for the most renowned wineries in the world and is involved in various infrastructure and engineering projects globally.

But Amorim is more than just stoppers. The harvested cork is used entirely, with zero waste, and this precious material has found increasing applications over the past decades, from insulation or flooring materials to drive belts and aerospace industry parts.

Visits to Wineries

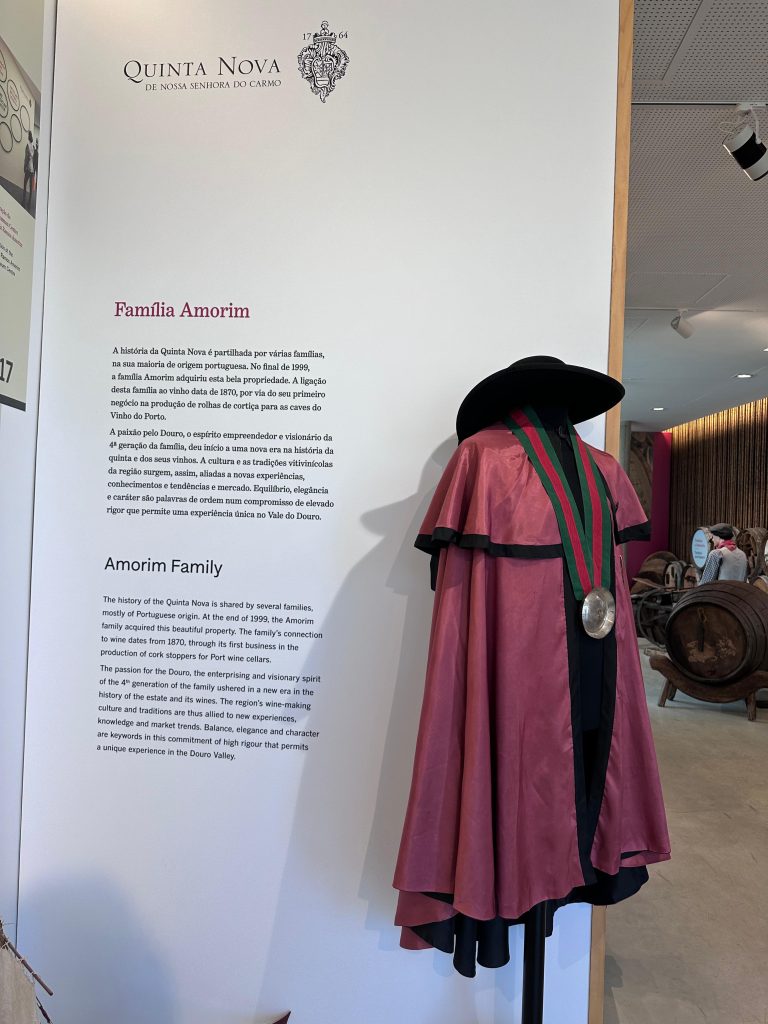

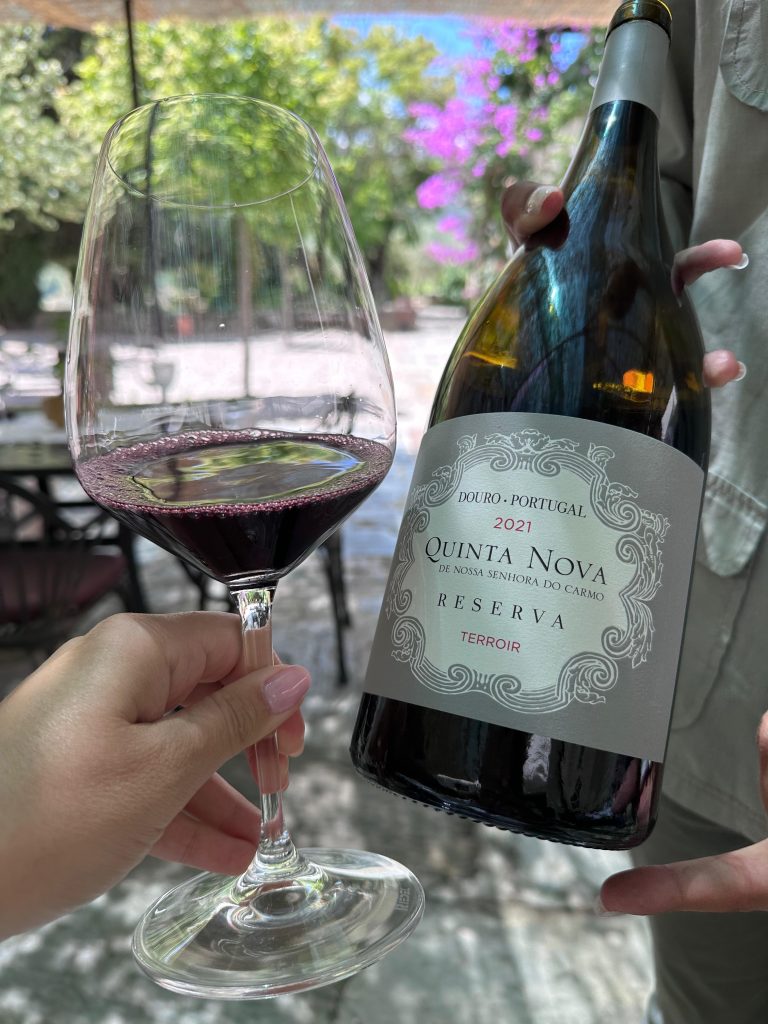

During my journey, I had the pleasure of visiting two renowned wineries. The first was Quinta Nova de Nossa Senhora do Carmo in the Douro region, which, along with Quinta da Taboadella in Dao, is part of the Amorim family. Quinta Nova de Nossa Senhora do Carmo is an old winery whose cellar was built in 1764 after the vineyard had been owned by the royal Portuguese family until 1725. Since 1999, it has been one of the properties of the Amorim group, managed by Luisa Amorim, who handles the family’s wine business.

Another wonderful surprise was the visit to Murganheira, a place I visited following the advice of Ernesto Pereira. Here, I discovered a large-scale winery with only 30 hectares of its own vineyard but with another 1,000 hectares owned by associated grape suppliers. The entire area is closely monitored year-round by Marta, the winemaker, whose story would take days to tell in full. But yes, as Ernesto had warned me, wonderful wines and wonderful people!

Instead of Conclusions

I arrived in Portugal thinking I knew the basics about stoppers. Agglomerated, twin-top, pearl, reconstituted… I learned how much more there is to know. Amorim is more than a company. It is an organism and a family. It is a set of values deeply rooted in every cell and a hopeful gaze towards the future. It is a model of practices, a model in research and innovation, and, let’s face it, a force. One that I hope will inspire many other businesses with its business model.